Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can ...

Raw Material Vertical Roller MillOur raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River Materials Group Phoenix Cement Plant Lee Gorby

Raw Material Vertical Roller Mill Our raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to ...

The vertical roller mill,also called vertical grinding mill,is widely used for cement,clinker,coal, steel slag, raw materials,nonmetallic a leading China vertical mill manufacturer,Great Wall provide roller mill with reasonable price.

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain ... By replacing ball mills with vertical or horizontal roller mills in raw material ...

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only ...

CHAENG GRMR raw material vertical mill is designed for cement raw material grinding system research and design of new type high efficiency, energy saving grinding equipment, production capacity of up to 720 t / h, the system ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and ...

Raw Material Vertical Roller Mill For Cement Plant, Energy Saving Vertical Roller Mill For Raw Material, Raw Material Vertical Roller Grinding Mill Cement Production Line Jiangsu Pengfei Group Co.,Ltd English ...

Pfeiffer Cement industry news from Global Cement OYAK Group orders three vertical roller mills from Pfeiffer ... An MPS 4500 B with a drive power of 3150kW will be used for cement raw material grinding. The mill... Loesche Mills for ...

1 Item Vertical roller mill for raw materials Application p rocess Raw material process Background Grinding raw materials needs lots of energy. Tube mills had been used for grinding, but the energy efficiency level was lower.

2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second half of the 20th century. Loesche was and is the pioneer of this technology. Hundreds of Loesche mills have ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small roller mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can ...

5 The core components of the roller mill include: xthe wearprotected grinding table with double groove grinding track xtwo roller pair units which adapt independently to the bed of material by vertical movement and by pivoting around ...

Vertical roller mill for cement grinding Finishing process Background In the cement grinding process, grinding system using the tube mill is widely applied for long year. Recently, especially from 1980s, grinding system using the ...

Application of Vertical Roller Mill: Vertical mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum ...

Vertical roller mill is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke .

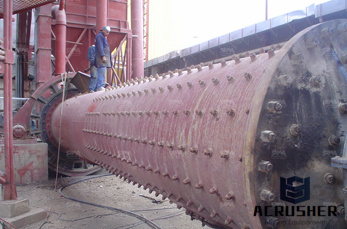

Ball mill is a kind of mineral material grinding equipment, because its interior is equipped with steel ball so Cement Mill Cement mill is an important part of the cement plant equipment, as used to grind raw material ...

Design advantages The modular design has parts commonality with OK raw mill, resulting in reduced spare parts inventory and consistent maintenance practices The patented cement grinding profile is the only one in the market ...

FL – ATOX® Raw Mill The ATOX® raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials. forces and dynamic reactions are small and vertical and thus easy to ...

The lining board and rollers of the Raw Material Vertical Roller Mill jointing with the German imported welding stick, has characteristics of powerful wearresisting, corrosion resistance, heatresistance, and can reduce operating cost ...

Mills and Components Power Europe Service feed size of vertical raw mill lm 32. Description : machines for units to all mill sizes for example classifiers for . lish the grinding of cement in vertical mills. Raw Material ...

64 CEMENT INTERNATIONAL 4 2/2013 4 VOL. 11 ZUSAMMENFASSUNG Cement production typically requires the grinding of three separate types of material during the process: the raw ma terials and coal before the kiln, and the ...

WhatsApp)

WhatsApp)